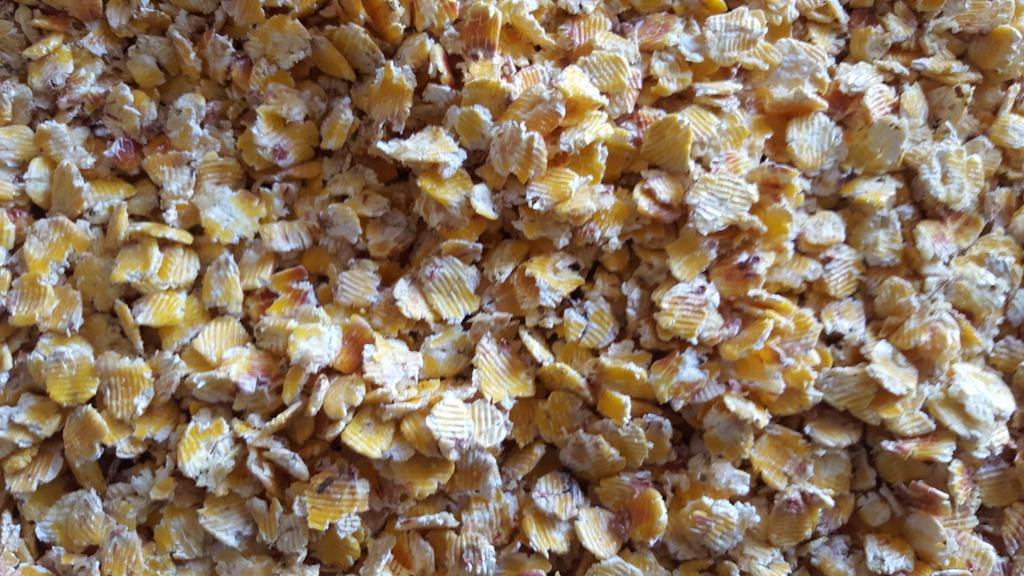

Steam flaked corn

Corn flakes produced in the company's factory screening and cleaning and moisturizing and macerating corn for 24 hours, then cooked with steam under pressure at a temperature of 100° C, for 60 minutes and passed in a special piston between the large diameter heated cylinders Trgigaha hot and under hydraulic high pressure, and lead manufacturing method this increased to digest corn for cattle coefficient, where Etjltn starch and other foodstuffs and increase their representation rate and benefit the animal, including 15-20% for corn is processed in dairy cows and 18-19% in the calves. Net energy to save more than 15% and net energy for growth of more than 18% than in corn flakes, according to the experiences of field of nutrition. It can feed them by 40% of the bush. It is worth mentioning that the nutritional values of the atom Alciltn way moisturizing and drenching then steaming and attenuation in feedstuffs tables much less than their true value, which scored in the field of nutrition experiments ... Because scheduled values overlooked improvement in digestive organic material non-starchy same amount of digestive starch improverment (10% at least)